If the installation of the WCPS in-floor or WCPS raised floor solution is not possible in certain manufacturing and logistics areas, but robots are to be supplied with

power contactlessly via the underfloor in these environments, the WCPS ramp solution takes on an important role as the raised floor infrastructure.

Solution

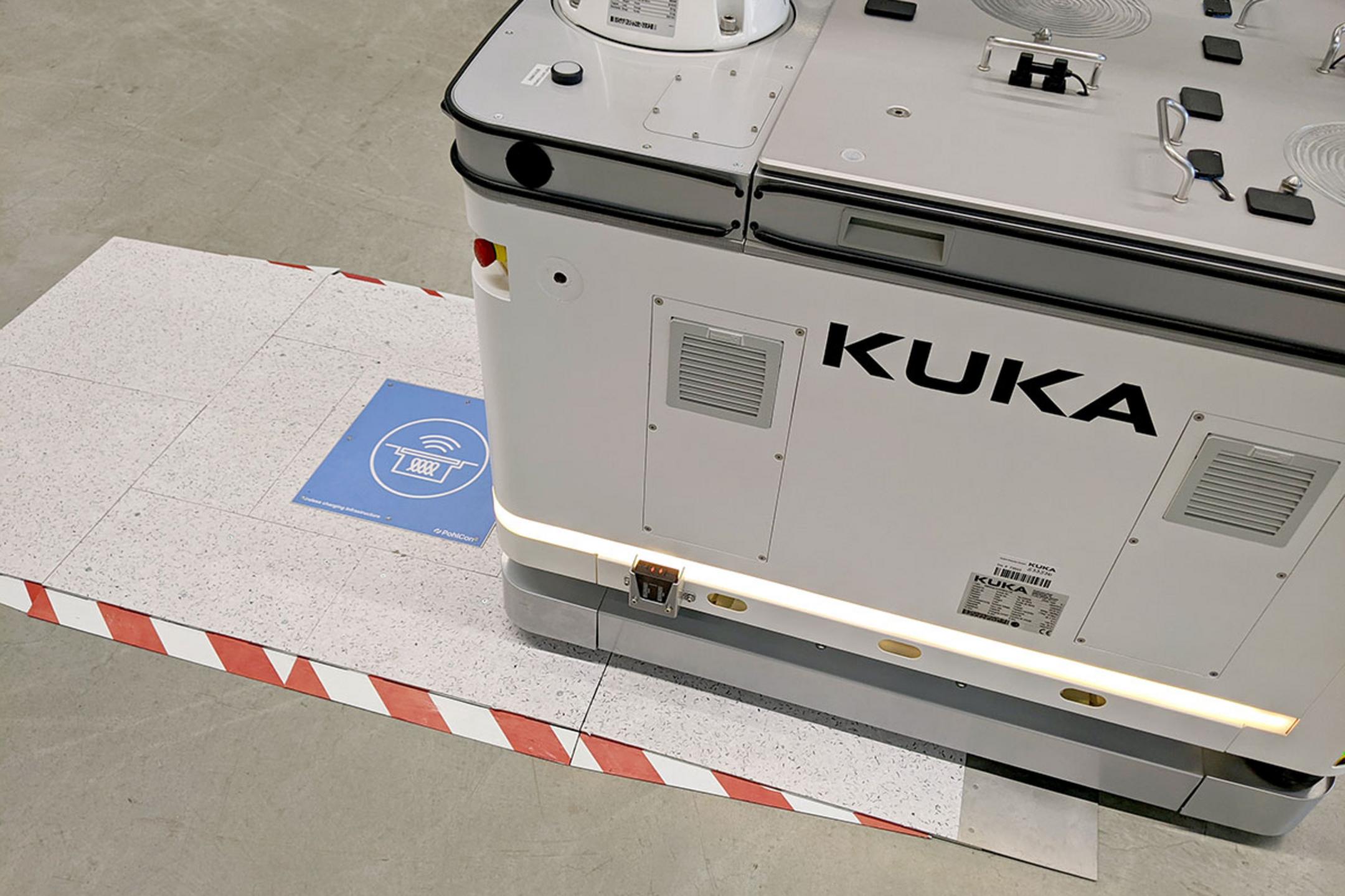

The developed, very flat WCPS ramp system serves as a protective on-floor charging infrastructure for the contactless energy transfer technology. This makes it possible to contactlessly charge autonomous robots in the work process without structural intervention in the floor and without them having to leave the work area. The WCPS ramp system is positioned in or along travel paths in order to be able to recharge the AGV during short stopping times.

Result

- Maximum availability of the robots thanks to safe energy supply in demanding working environments

- Walk-on and drive-over capability of the charging infrastructure

- Extremely slim basic design

- Easy expansion of the infrastructure on all routes thanks to modular design

- Ensuring a constant battery level along the working route

- Can be used in clean rooms up to ISO3 (material classification)

- Load capacity up to 500 kg wheel load

- Length: 2088 mm / Width: 800 mm / Height: max. 21 mm / 3% slope

Current Project

The initial use of the WCPS ramp was at a large American semiconductor manufacturer and enables contactless charging within the production zones in highly demanding ISO3 clean rooms. During process-related stops along the semiconductor manufacturing line, the robot is reloaded contactlessly without having to leave the work process. This optimizes fleet utilization and minimizes non-value-added empty runs and traffic.

The robot used

KMR stands for KUKA Mobile Robotic. The KMR iiwa is a combination of the sensitive lightweight robot LBR iiwa and a mobile, flexible platform. As the name and the individual components already reveal, the KMR iiwa is characterized by high mobility and flexibility. Manufacturing processes are permanently changing. That is why mobile robot systems must be all the more adaptable. Maximum mobility and autonomous modes of operation optimize the production significantly.

Find more information in the Case study.