Smooth concrete surfaces and flexibility in the construction process thanks to formwork tubes from PohlCon

Degelo Architects remodeled the University Library building in Freiburg, Germany, by converting the existing grid of vertical exposed concrete columns into angled, individually placed columns. Almost 500 reinforced concrete columns were used, manufactured with RAPIDOBAT® formwork tubes from PohlCon to achieve seamless exposed concrete surfaces. The conversion provided 20% more usable space despite a 20% reduction in volume. The challenge was to react sensitively to the heterogeneous surroundings and to make various uses such as a reference library, a new media center and individual workstations a functional experience.

Design concept

The concept for the renovation of the 1970s building involved cutting off the floor slabs and interpolating the indentations in order to calm the volume and strengthen the presence of the structure. During the planning process, the client decided on an extended deconstruction and the replacement of all above-ground ceilings. The differentiated façade surfaces were reduced, resulting in a 70% saving in energy consumption compared to the existing building. The materials, in particular chrome steel panels and glass, reflect the surroundings and integrate the library into its environment.

The sloping reinforced concrete columns

Degelo explains that the original building had a simple load-bearing structure with a column grid of 7.5 meters. By reducing the floor slab, part of the structural system was lost, so new columns were placed where necessary. This transferred the forces directly into the unchanged basement floors and foundations. The inclination of the columns was based purely on engineering considerations, resulting in 34 different inclinations.

Precise production and flexible delivery of the formwork tubes

The construction company Moser Bau from Merzhausen near Freiburg carried out the work. They constructed around 300 reinforced concrete columns with diameters of 40 cm, 70 cm and 80 cm as well as over 180 inclined columns. The use of RAPIDOBAT® formwork tubes from PohlCon was the first choice due to their flexibility and the possibility of obtaining them in the required dimensions. The formwork tubes were ordered in sections according to the structural engineer's plan specifications and fitted perfectly. As the manufacturer, engineers from PohlCon were also on site to advise on details and even implement unusual shapes such as the Y-shape of the formwork tubes.

Seamless exposed concrete surfaces

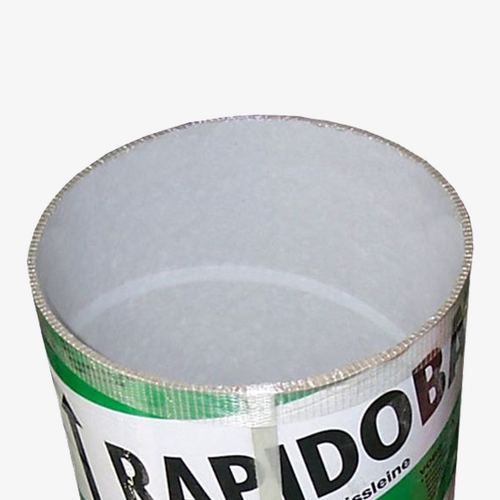

The shell construction company emphasized the flexibility and seamless surface of the formwork tubes. The "smooth-light" formwork variant for exposed concrete class 2 creates barely visible joints. Architect Degelo praised the shell construction and was very satisfied with the finished columns.

When asked whether they would use RAPIDOBAT® formwork tubes from PohlCon again for other construction projects, the architect and shell construction company agreed - "Yes".