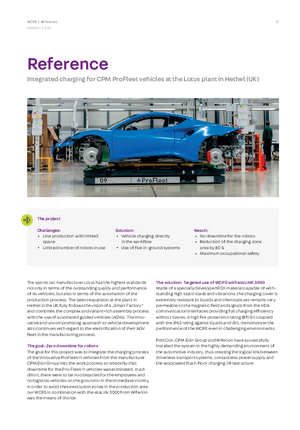

The sports car manufacturer Lotus has the highest standards not only in terms of the outstanding quality and performance of its vehicles, but also in terms of the automation of the production process. The latest expansion at the plant in Hethel in the UK fully follows the vision of a „Smart Factory“ and combines the complex and variant-rich assembly process with the use of automated guided vehicles (AGVs). The inno-vative and uncompromising approach to vehicle development also continues with regard to the electrification of their AGV fleet in the manufacturing process.

The goal: Zero downtime for robots

The goal for this project was to integrate the charging process of the innovative ProFleet-11 vehicles from the manufacturer CPM Dürr Group into the work process so smoothly that downtime for the Pro-Fleet-11 vehicles was eliminated. In ad-dition, there were to be no obstacles for the employees and no logistics vehicles on the ground or in the immediate vicinity. In order to avoid these exclusion zones in the production area our WCPS in combination with the etaLink 3000 from Wiferion was the means of choice.

Find more information in our Case Study.

PDF | 97 KB

PDF | 97 KB