Networking, automation, artificial intelligence - all key factors of the fourth industrial revolution, known as Industry 4.0. Among other things, they are intended to ensure that the manufacturing industry remains competitive and production costs can be reduced. To achieve this goal, companies are increasingly turning to mobile robotics.

The advantages of autonomous mobile robots are beyond question, but industrial vehicles still have a crucial weak point: their energy supply. Up to 32 percent of operating time is lost to charging the batteries alone. The charging stations also require a lot of space, which could be used for production processes under better charging conditions. These obstacles can be avoided with the help of contactless energy transmission.

WCPS on the international stage

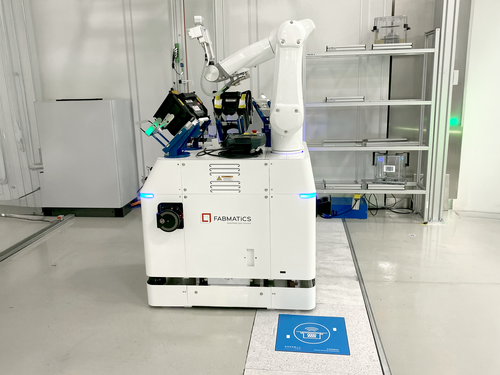

PohlCon is supporting this development with its own in-process charging product, the Wireless Charging Protection System (WCPS). We presented the contactless charging infrastructure for autonomous mobile robots at two renowned trade fairs in the robotics industry: the Robotic Summit in Düsseldorf and Logimat Southeast Asia in Bangkok. Our cooperation partner Wiferion was also represented at both trade fairs as part of the PULS Group. The company manufactures the loading pads that our WCPS protective housing accommodates.

PohlCon and the growing robotics market

We presented WCPS as part of an exclusive showcase at the Robotic Summit. The collaboration with a content creator from the logistics sector also increased our presence at the event. The positive feedback was reflected, among other things, in the large number of discussions that our trade fair team was able to hold on site.

Logimat Southeast Asia also provided PohlCon with a very good platform to present the WCPS to an international audience of experts. Thanks in particular to our participation in the “German Pavilion”, there were many opportunities to exchange ideas with regional distributors and robot manufacturers as well as with PULS representatives from Japan, South Korea, Singapore and Thailand. We are particularly pleased with the strong interest shown in our product by industry giants such as Yamaha, Fuji, Bosch and Toyota. A solid basis for future partnerships and projects.