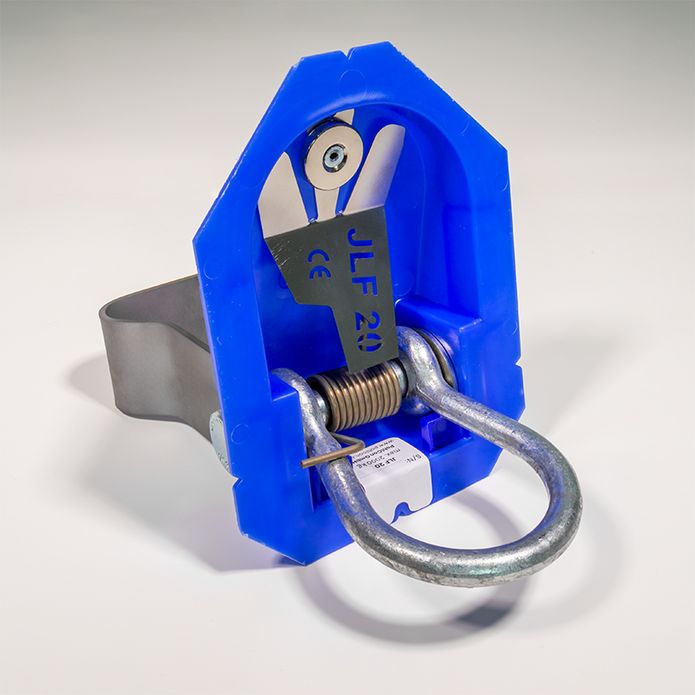

Assembly or maintenance work in elevator shafts requires reliable fastening solutions. After all, these are measures that often take place at great heights in combination with heavy loads. The JLF elevator shaft anchor of our Jordahl brand has been developed to allow easy and thus time-saving use when working in elevator shafts. The essential components, the stirrup anchor and the steel shackle, are fixed in the housing: This means that the slim steel shackle, which is flush with the ceiling, does not have to be pulled out awkwardly when in use. Instead, the system features a new type of magnetic snap lock that is activated by pressing on a clearly visible release plate, for example with the help of a metal rod. When the work is finished, the shackle can simply be pushed back into its original position. In this way, material loads, for example protective equipment or spare parts, as well as suspended elevator cabs, can be quickly fastened temporarily.

With our lift shaft tanker, you're simply faster:

Thanks to the integrated rocker, the JLF folds out at the push of a button.

- Magnet secures the folded shackle in the housing.

- Slim shackle shape offers more space and thus facilitates hooking.

- High safety of the product confirmed by approval (ETA-21/1071).

Two versions for different load requirements

The lift shaft anchor is initially available in Germany and Switzerland in the two versions JLF 20 and 40 with the corresponding load capacities. The color scheme of the plastic housing in blue (20 kN) and red (40 kN), which is familiar in specialist circles, also enables reliable differentiation here from a distance. A secure and permanent connection in concrete is ensured by the stirrup anchor with 130 or 190 mm installation depth, which permits use with slab thicknesses from 150 mm (JLF 20). Both types are designed for centric tensile loads. They are therefore suitable for inclined tensile loads of up to ± 5°.

Quick and easy installation of the elevator shaft anchor

For installation, the elevator shaft anchor is nailed to the wooden formwork via the nail holes in the cover after appropriate positioning and the slab is then concreted as usual. During the subsequent stripping of the formwork, the cover is usually removed at the same time and can alternatively be pulled off the casing manually via the integrated recess in the cover. Both JLF types are supplied as ready-to-install components and are approved for material loads in accordance with European Technical Assessment (ETA 21/1071). For maximum convenience already during assembly, the housing lids are each provided with a QR code with which fabricators can digitally retrieve the assembly instructions.