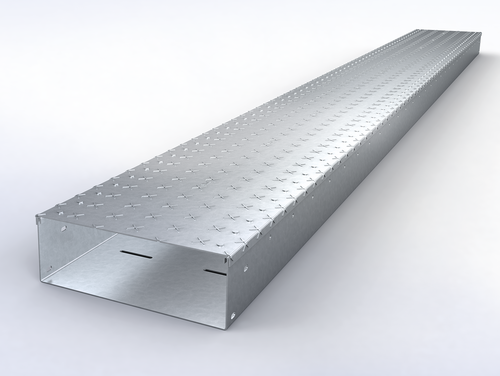

Floor-level cable tray systems are used in the manufacturing industry, e.g. in plant construction in the automotive industry, and in the supplier industry - i.e. wherever numerous data and power cables as well as pneumatic and hydraulic lines have to be routed along the floor due to a high degree of automation. These can be laid in an orderly and safe manner in the floor ducts from PohlCon, which are completely closed to the outside, and thus reliably protected from flying sparks, dirt and other mechanical effects. The floor ducts ensure that the cables are routed in accordance with the standards and in a professional manner. Therefore, they are an important component for a smooth production process.

Maximum work safety

Thanks to the resilient covers with exceptionally high non-slip embossing, the floor ducts from PohlCon are completely walkable and slip-proof: We guarantee a tested and certified load-bearing capacity of 5 kN according to DIN EN 50085 for our cover BKD-RHP as well as a non-slip class R12 according to DIN 51130 and DGUV regulation 108-003. This high non-slip class also applies to the covers for formed parts with the type designation RHP and thus ensures the corresponding slip-proofness in everyday industrial life – an essential factor for occupational safety.

Easy to install and flexible

We attach great importance to ease of assembly! Our extensive portfolio of formed parts enables flexible and installation-friendly laying of floor ducts in industrial halls and production facilities without the need for additional special tools. Even the shortening of individual parts is usually not necessary, as the floor ducts can be easily adapted to the conditions on site, thanks to the variable formed parts, the short sections and our telescope insert. With the help of the telescope insert BKTE, flexible length compensation between 150 and 650 mm is possible. No cutting work, no flying sparks.

Protected all round

Floor ducts must be included in the equipotential bonding of the entire system to protect against electric shock and to protect electrical equipment: They must be earthed. Our floor ducts are provided on the sides with pre-stamped, easily knocked out slugs to which the corresponding equipotential bonding terminal blocks can be attached.

To prevent electromagnetic interference, data lines and power cables must be routed separately. Depending on the width of the floor duct, one or two separating strips are used here. In addition, the separating strips ensure optimum dissipation of the vertical payloads acting on the system. With the help of the Z-profile BKZ, which is unique on the market, additional cables that are to be routed separately from other cables can also be separated within the floor duct system.

The floor duct side coverings serve to provide slip resistance for elevated floor ducts and prevent dirt deposits underneath the floor ducts.

You can find all the advantages and product features in our new Technical Information. Or find a contact person in your region right here.